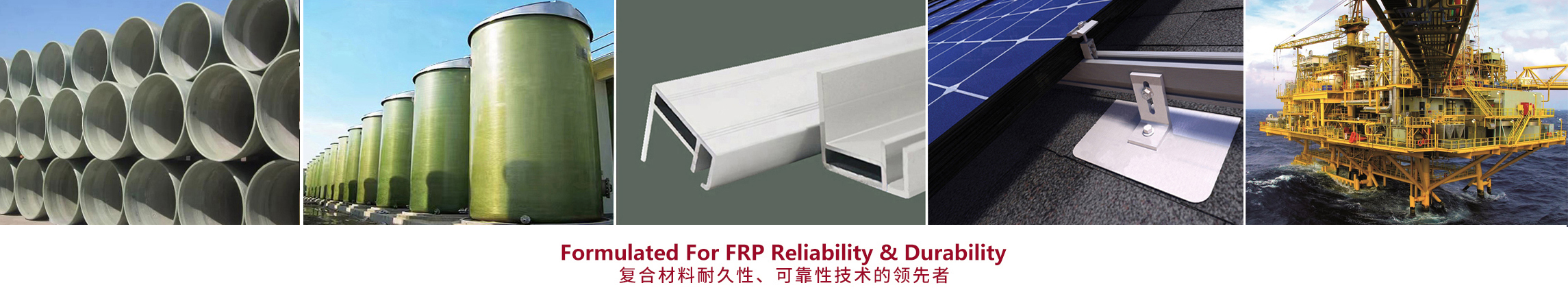

Advanced aliphatic polyurethane resin system for filament winding process has superior properties of UV resistance and anti-aging performance, which can greatly enhance the product reliability of filament wound FRP products and expected upwards of 80+ years of product service life.

The high performance polyurethane resin system has been rigorously tested by two highly reputable testing organizations in the United States and in China.

• UV Resistance, Anti-aging Performance:

8,000 Hours (ASTM G154-2016)

• Working Temperature:

-40°C - 90°C

• Predicted Service Life:

80+ years

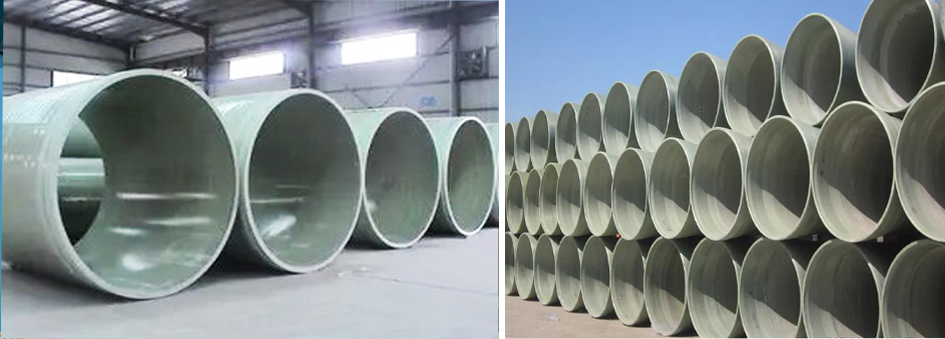

• Application:

Above-Ground FRP pipe manufacturing